The null hypothesis is that there is no difference between the mean time it takes an online trained employee or a team-based trained employee to assemble the given part

Step-by-step explanation:

The information the director of the equipment manufacturing company is interested in determining is weather the productivity of assembly line employees is affected by the method used in their training

The total number newly hired employees in the sample = 42

The number of newly hired employees that receive training online = 21

The number of newly hired employees that receive training in a team = 21

The given data of the result of the time it takes an employee to assemble a part is presented as follows;

On-Line 19.4, 16.7, 20.7, 19.3, 21.8, 16.8, 14.1, 17.7, 16.1, 19.8, 16.8, 19.3, 14.7, 16.0, 16.5, 17.7, 16.2, 17.4, 16.4, 16.8, 18.5

Team; 22.4, 13.8, 18.7, 18.0, 19.3, 20.8, 15.6, 17.1, 18.0, 28.2, 21.7, 20.8, 30.7, 24.7, 23.7, 17.4, 23.2, 20.1, 12.3, 15.2, 16.0

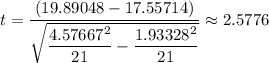

The mean time for the of the on-line trained employee,  = 17.55714

= 17.55714

The standard deviation of the time for the of the on-line trained employee, s₁ = 1.93328

The mean time for the of the team based trained employee,  = 19.89048

= 19.89048

The standard deviation of the time for the of the team based trained employee, s₂ = 4.5667

The null hypothesis, H₀:  =

=

The alternative hypothesis, Hₐ:  ≠

≠

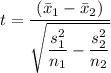

Therefore, we have;

The degrees of freedom, df = n₁ - 1 = 21 - 1 = 20

At 95% confidence level, we have α = 1 - 0.95 = 0.05, and t = 2.086

Therefore, given that the test statistic is larger than the critical 't' value, we reject the null hypothesis. There is sufficient statistical evidence to show that there is a difference between the mean time of assembly value for the on-line trained and team-based employee